Welcome back to the SDG Connection blog series as we illustrate that what we do in Devens aligns with the United Nations Sustainable Development Goals (SDGs). This month we will explore the Waste-Climate Connection by looking at how this former Army base is transitioning to the circular economy.

Understanding the Waste-Climate Connection

Our decisions about how we (re)use and dispose of materials can make a big difference on the amount of raw resources used, greenhouse gases emitted, and general environmental impacts created. It takes resources, energy, and land to produce, transport, and dispose of things. Waste can also contribute to local environmental pollution and degradation in our community.

The concept of the 3 R's (Reduce, Reuse, Recycle) helps us create a new paradigm. Reducing consumption is the most important aspect where we as consumers of products have a role to play through our decisions on what products to purchase. By designing for the environment from the start, manufacturers can design products, which can be disassembled and reused instead of landfilled.

Making better decisions about waste, including finding homes for used products such as the wood pallet exchange between Maxant Industries and Vulcan Forms, can reduce our climate impact and improve quality of life in Devens.

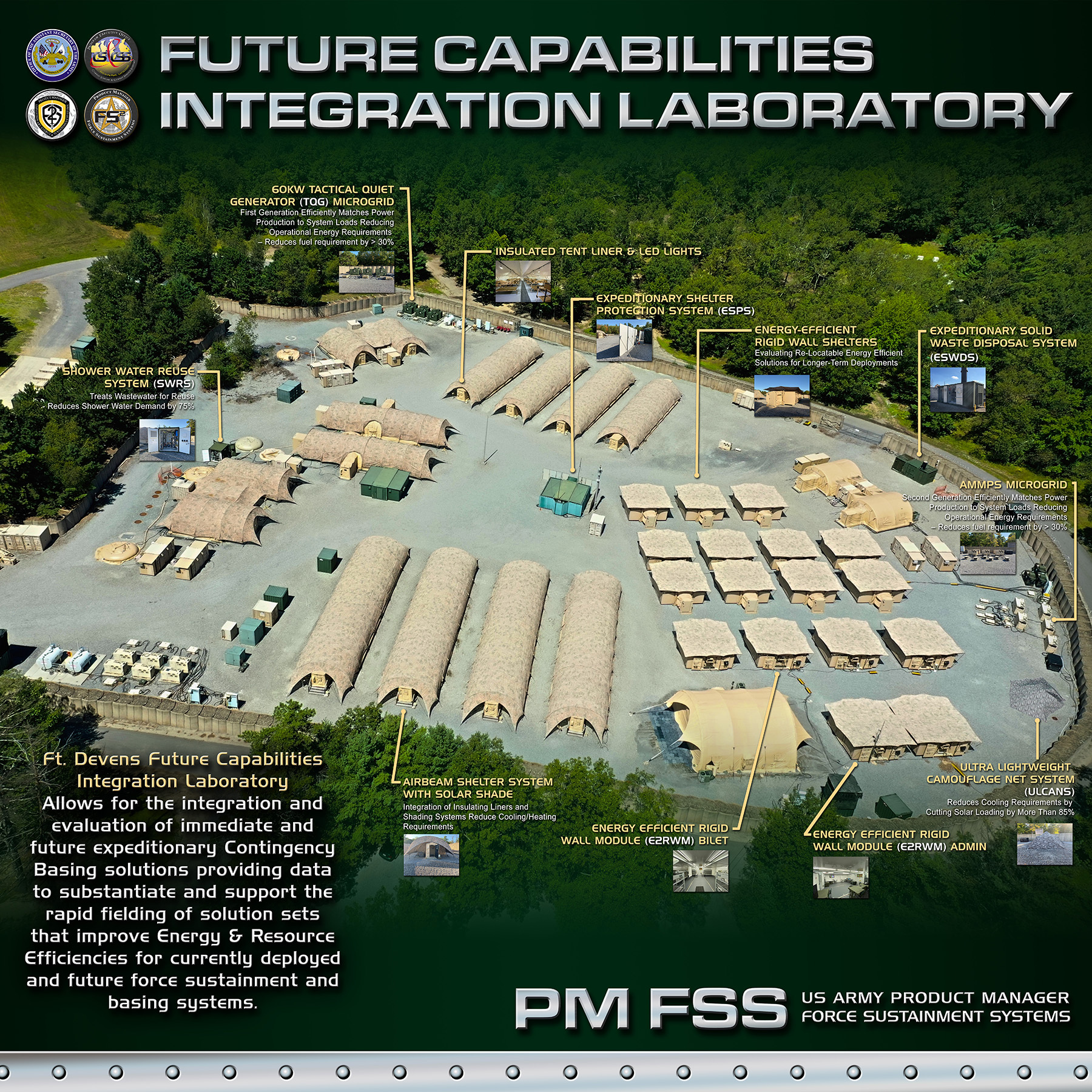

The remaining military uses in Devens are also exploring operating more efficiently. The Future Capabilities Integration Lab (FCIL) replicates a forward operating base in a deployed environment, designed for evaluating new contingency basing sustainment & protection equipment. The FCIL provides the opportunity to evaluate housing solutions for troops that could improve resources and are more energy efficient.

SDG Connection: Local Waste and Global Climate

How we handle waste can help us to achieve the UN SDGs, namely:

- SDG 12: Responsible Consumption and Production

What is the Circular Economy?

With the circular economy we strive to replace the straight line paradigm of production, consumption, and waste with a circular theme based on adding the concept of Return or Reuse to the equation. In this paradigm, we may think of waste as orphan products seeking a new home.

Implementing the circular economy in Devens is not just about reducing waste but also has many economic development benefits. The eco-industrial park component built into Devens is based on facilitating material by-product exchanges (often called industrial symbiosis). Our Devens Eco-Efficiency Center was created to facilitate these exchanges and to assist businesses in the region to green their operations. By reselling and repurposing materials from the film and television sets at New England Studios, Hollywood Salvage are repurposing materials and keeping them out of the landfill while each firm saves money. Data shows that sustainable businesses can perform better financially, improve productivity, and attract customers and talent.

What is Devens Doing to Support the Circular Economy?

Devens is taking action as part of the Devens Forward Plan to become a regional hub for resource recovery and sustainable materials management, and with the Devens Eco Efficiency Center we are working with our businesses to design waste out of systems and encourage by-product exchanges.

The Devens Eco Efficiency Program manages the Great Exchange program, which facilitates by-product exchanges and repurposes products and excess materials, over 1350 pounds through the first three quarters of 2021. The materials run the gamut from office supplies to furniture and largely benefit nonprofits, schools, and members of our regional business community.

The Great Exchange, a program run out of the Devens Eco-Efficiency Center, prevents waste and provides savings opportunities for reuse of lightly used items.

Republic Services’ Construction and Demolition Debris Devens Recycling Facility kept over 16,042 tons of material out of the landfill in just the first three quarters of 2021.

Sustainable Business Spotlight: Little Leaf Farms

Let’s take a closer look at Little Leaf Farms and the sustainable business practices and material exchanges it supports. Neil Angus, AICP, an Environmental Planner at DEC, interviewed Little Leaf Farm staff in November 2021.

Ecological Exchanges:

- Water Conservation: Little Leaf greens are grown hydroponically using 100% captured rainwater. They use an advanced fertilization and irrigation system that uses 90% less water than field-grown greens. With an automated growing system, there is no need for soil or pesticides, so they do not need to wash the lettuce before packaging which saves thousands of gallons of water.

- Energy Conservation: Little Leaf’s natural gas heating system is designed to capture carbon dioxide and reuse it to optimize plant growth instead of releasing it into the atmosphere.

- Natural Sunlight: Their greenhouse is built to maximize the use of natural sunlight. They use unfiltered glass and supplement with LED-powered grow lights in the winter months that consume 40% less electricity than conventional grow lights.

- Natural Pest Control: Little Leaf plants pollinator gardens around their facility to aid in habitat restoration as well as pest control and makes use of natural control methods in their greenhouses. Little Leaf is also partnering with Best Bees to provide bee hives around the facility and with the New England Forestry Foundation to help plant a more productive forest surrounding the facility.

- Peat Moss: Little Leaf uses peat moss for their growing medium and the peat is delivered in white plastic wrap which is also sent to a 3rd party for reuse and recycling.

Sustainability:

In addition to the above, Little Leaf is advancing the goals in the Devens Forward Plan in their day-to-day operations.

- Food Miles: 98% of lettuce in the U.S is grown in California and Arizona. The lettuce in our New England stores is shipped over 3,000 miles, sacrificing freshness and fuel each day it spends on a truck. Little Leaf Farms delivers our greens to stores within a day’s drive – maximizing freshness and minimizing our impact on the environment.

- Packaging: Little Leaf is actively working on packaging options that use less plastic. Their current packaging uses 100% post-consumer recycled plastic, and they will be switching to a new packaging design that will use 35% less plastic than the current clam shells. Little Leaf also partners with West Rock in Devens on a cardboard take-back program.

- Equity: Sustainability isn’t just about environmental or climate impact. Little Leaf is partnering with local organizations like Seven Hills Aspire Program to support individuals with disabilities, as well as with Clear Path for Veterans and Loaves and Fishes Food Pantry to provide food for those in need.

What Can Residents and Businesses Do?

Interested in reducing waste at home or work? Here are six tips:

- Give the gift of experiences this holiday season to reduce consumption.

- Shop local in Devens to reduce waste associated with transport of items and support local businesses. $.68 of every dollar spent locally stays in the community and is a reason why we support the Nashoba Valley Chamber of Commerce’s Shop Local and Win Winter program.

- Businesses in Devens can work with other local businesses to get creative about material exchange and reuse.

- Create a collection bin in your home/business and make sure you know what Devens Recycling Center accepts.

- Go reusable: bring a reusable cup or bag with you when you’re on the go.

- Learn about how you can compost at home.

We encourage readers to look at past blog posts in this series and to check out the actions in the Plan if you want more information about what Devens is doing about material management and circular economy

Previous Post

Green Team Roundtable: Redirecting Waste Streams

Next Post

Sustainable Business Spotlight: SMC